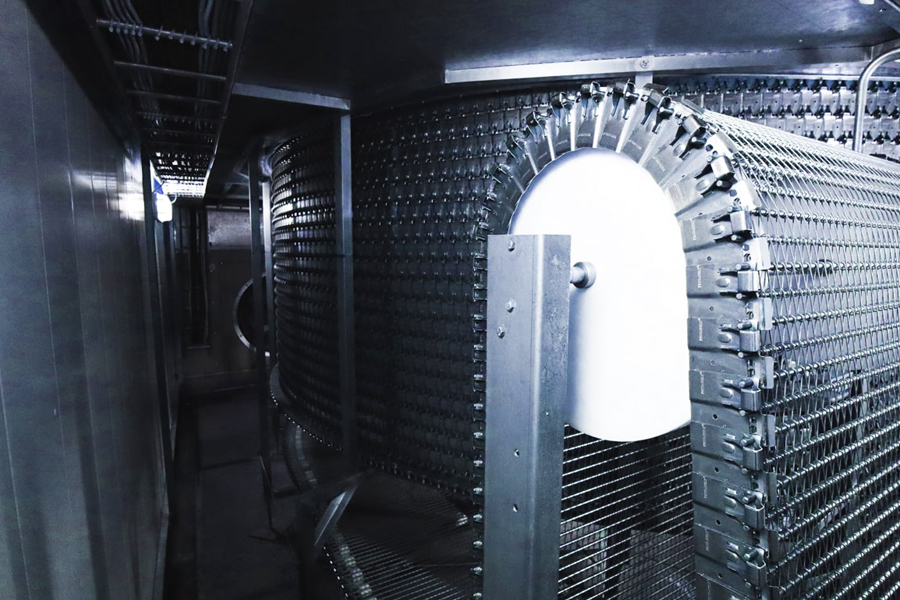

Enhance food processing efficiency with reciprocating compressors

Image Source: www.industrialfreezing.com

Reciprocating compressors play a vital role in these systems, providing the necessary compression for refrigerants to cool and preserve food products effectively. If you’re in the food industry and seeking reliable refrigeration solutions, investing in reciprocating compressors could be a game-changer for your operations. Let’s explore why.

Understanding reciprocating compressors

Reciprocating compressors are positive displacement compressors that use pistons driven by a crankshaft to compress gas and deliver it at high pressure. These compressors are known for their reliability, versatility, and ability to handle varying refrigeration loads efficiently. They are commonly used in a wide range of refrigeration applications, including food processing, cold storage, and air conditioning.

Why choose reciprocating compressors for the food industry?

1. Reliable performance:

Reciprocating compressors are renowned for their reliability and durability, making them well-suited for the rigorous demands of the food industry. Their robust construction and simple design minimize the risk of breakdowns and ensure continuous operation, even in challenging environments.

2. High efficiency:

Reciprocating compressors offer high efficiency across a wide range of operating conditions, making them cost-effective solutions for food processing facilities. They can efficiently handle varying refrigeration loads, providing consistent cooling while minimizing energy consumption and operating costs.

3. Flexibility:

Reciprocating compressors are highly versatile and can be adapted to suit different refrigeration system requirements. Whether you need a compressor for low, medium, or high-pressure applications, reciprocating compressors offer the flexibility to meet your specific needs.

4. Ease of maintenance:

Maintaining reciprocating compressors is relatively straightforward, thanks to their simple design and accessible components. Routine maintenance tasks such as oil changes, filter replacements, and inspections can be easily performed, minimizing downtime and ensuring optimal performance.

5. Wide range of applications:

Reciprocating compressors find applications across various sectors of the food industry, including meat processing, dairy processing, beverage production, and cold storage. They are capable of handling a wide range of refrigerants and operating conditions, making them versatile solutions for diverse food processing operations.

Applications of Reciprocating Compressors in the Food Industry

Reciprocating compressors are used in a wide range of food processing applications, including:

Refrigerated warehousing:

Reciprocating compressors are commonly used in cold storage warehouses to maintain optimal temperatures for storing perishable goods such as fruits, vegetables, meats, and dairy products.

Food processing:

Reciprocating compressors play a crucial role in food processing facilities for tasks such as freezing, chilling, and preserving food products. They are used in refrigeration systems for blast chillers, freezers, refrigerated display cases, and more.

Beverage production:

Reciprocating compressors are used in beverage production facilities for tasks such as cooling, carbonation, and packaging. They help maintain the quality and freshness of beverages throughout the production process.

Conclusion

Investing in reciprocating compressors for your food processing operations can significantly enhance efficiency, reliability, and product quality. With their proven performance, versatility, and cost-effectiveness, reciprocating compressors are indispensable assets in the food industry. Whether you’re running a small-scale food processing facility or a large cold storage warehouse, incorporating reciprocating compressors into your refrigeration systems can help you meet the demanding requirements of the industry while ensuring the integrity and freshness of your products.